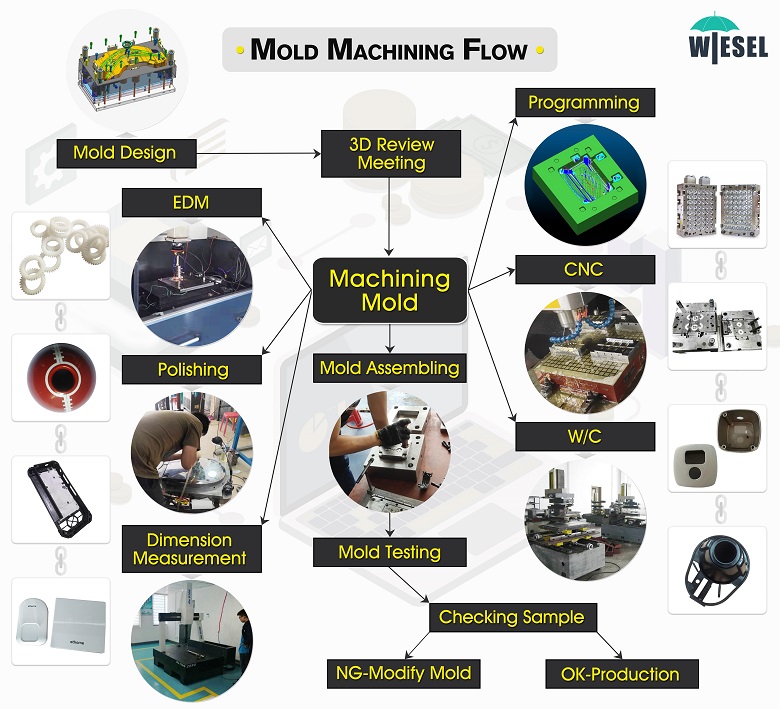

Wiesel specialize in various industries mold for customer

LEARN MORE

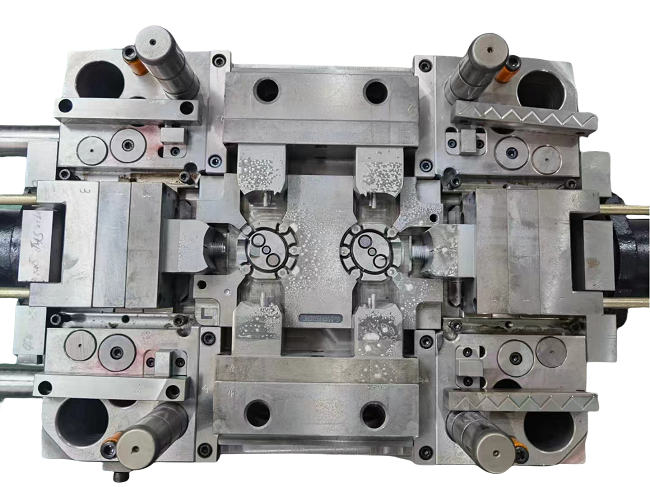

| Mold Type | Manufacturing | Moldlife |

| Harden Mold | Insert-heat treatment, CNC-Two times | more than 500,000 |

| Soften Mold | Not Heat treatment, Hardness is less | less than 100,000 |

There are many types of hardened and semi-hardened tool steels to choose from, including P20, 718H,NAK80, H13, and S136. They differ in the degree of corrosion resistance, toughness, thermal efficiency, and the ability to take a high polish.

That’s why the choice of tool material that’s best suited for your project depends on your intended production volume, the surface finish of the part, the type of resin that’s being injected, and the complexity of the tool design.

As with all tooling design decisions, we advise consulting with your manufacturing partner in advance to clearly understand your options.

Provide Comprehensive Product Technology Solutions

Free more information about Mold Manufacturing